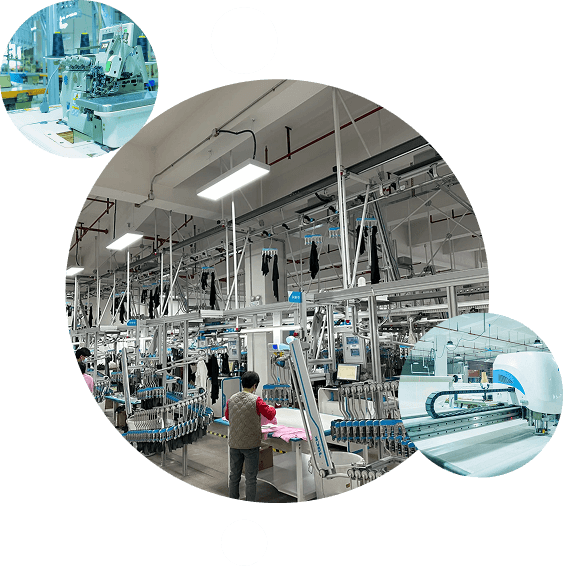

9 + 1 sewing line + 3 rear threads

A total of 410 stations with a daily production capacity of 15,000 20,000 pieces

The introduction of high-speed extended hanging main rail, up to 68 meters long, high-speed hanging transportation line.

I adopt sewing with The integrated production mode of post integration connects the sewing line with the post-wholeline It is connected by the main rail to realize the streamlined production management mode.

Its advantage is that the single product is produced quickly and the quality is controlled in a timely manner. Greatly improve production efficiency,rate, single shipment efficiency, reduce quality rework rate.

A sample garment, known as a proto sample or fit sample, is sewn using a preliminary pattern and a similar fabric.

This sample is used to check the design, fit, and silhouette on a live model or mannequin.

Once the base pattern is approved, it is graded—meaning it is systematically scaled up and down to create a full range of sizes (XS, S, M, L, XL, etc.).

A marker is created, which is a digital diagram that lays all the pattern pieces on the fabric in the most efficient way to minimize waste.

Fabric is then spread out in long, multi-layered plies on the cutting table according to the marker's length and ply height.